When sourcing trolley bags and luggage for your brand, choosing the right manufacturing partner is critical to ensuring product durability, functionality, and market appeal. As a custom luggage factory specializing in OEM/ODM services, we understand that quality starts with material selection, component engineering, and tailored design. Here’s a detailed guide to help you identify premium trolley bags and luggage while highlighting key factors that set exceptional manufacturers apart.

The choice of shell material directly impacts a product’s weight, strength, and aesthetic appeal. Here’s how to match materials to your target market:

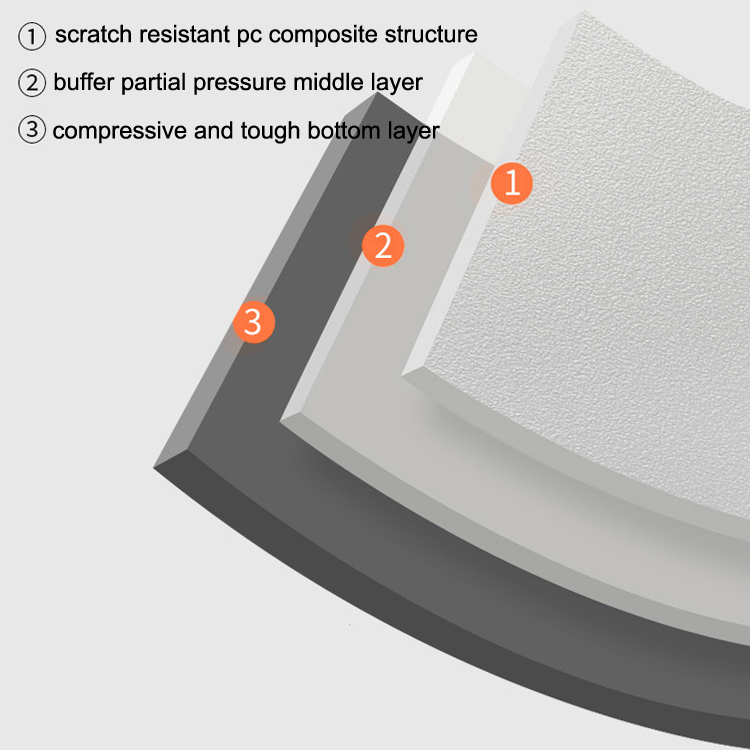

PC (Polycarbonate) & PP (Polypropylene): Ideal for hard-shell luggage, these materials offer lightweight durability and scratch resistance. PC is favored for premium luggage due to its flexibility and impact resistance, while PP suits budget-friendly yet sturdy designs.

ABS A cost-effective option for entry-level luggage, but prone to cracking under heavy stress.

Nylon: The go-to material for **carry-on trolley bags—lightweight, water-resistant, and perfect for frequent travelers.

PU (Polyurethane): Best for **fashion-forward trolley bags**, offering a sleek, leather-like finish at a fraction of the cost.

Why work with us? Our factory uses 2mm-3mm thicker PC, PP, and ABS sheets compared to standard suppliers, ensuring your luggage stands out with unmatched sturdiness.

The quality of zippers, wheels, handles, and telescopic rods can make or break a product. Components vary widely in cost and durability:

Telescopic Rods: Low-end aluminum rods cost 5-7x less than premium stainless steel or reinforced aluminum versions.

Wheels: Silent, 360° spinner wheels (high-end) vs. basic inline wheels (budget).

Zippers: YKK®-grade zippers for luxury lines or standard zippers for economy models.

A skilled factory will help you balance cost and quality based on your audience. For example, luxury brands benefit from aircraft-grade aluminum rods and TSA-approved locks, while budget lines can optimize costs with mid-tier components.

The interior lining is often overlooked but plays a key role in perceived quality. Common options include:

210D Polyester: Basic, cost-effective, but prone to wear.

230T Polyester: Mid-range, durable, and widely used for mid-tier luggage.

420T Polyester: Higher density for added tear resistance.

Satin: Reserved for luxury luggage, offering a soft, premium feel.

Cotton: Eco-friendly but less common due to maintenance needs.

*Our competitive edge: While most factories use 210D polyester, we specialize in satin linings for high-end collections and 230T polyester for mid-range lines. This subtle upgrade ensures your products feel more refined than competitors’.

Many factories cut costs by thinning shell materials, leading to fragile luggage. Key differences:

Standard Thickness: 3-4mm (common for ABS/PP).

Our Thickness: 5-6mm for PC, PP, and ABS, enhancing impact resistance without compromising weight.

This small but critical detail ensures your luggage survives rough handling, airport conveyor belts, and years of travel.

As a professional luggage manufacturer, we combine customization expertise with rigorous quality control:

Material Customization: Choose from 20+ shell materials and linings.

Component Flexibility: Mix and match parts to align with your brand’s price point.

Quality Assurance: Every product undergoes load, drop, and wheel spin tests.

Whether you’re launching a luxury line or affordable travel gear, our team ensures your trolley bags and luggage exceed market expectations.

Ready to create standout luggage?** [Contact us]www.osamicbags.com today for a free consultation and sample development!